Posted 4 days ago

Electric portfolio grows: Mercedes-Benz Trucks starts production of new eActros 400 generation at Wörth plant

Mercedes-Benz Trucks is expanding its portfolio of battery-electric trucks: Series production of the second-generation eActros 400 began at the Wörth plant in early December.

With numerous new combination options based on the two models, the eActros 400 and eActros 600, Mercedes-Benz Trucks is specifically expanding its range to meet even more logistics requirements in heavy-duty long-distance and distribution transport with electric vehicles. In the future, the manufacturer will offer the eActros as the eActros 400 with two battery packs and as the eActros 600 with three battery packs – each available as a tractor unit or flatbed chassis, depending on individual requirements in terms of application, range, and payload. In addition, customers will be able to choose between two cabs in the future.

Mercedes-Benz Trucks achieved a strong market share of almost 50 percent in Europe for heavy-duty electric trucks in the third quarter of the year. This makes the Daimler Truck segment the clear market leader – for the second quarter in a row. With the portfolio expansion now underway, the company aims to take on a pioneering role and is clearly focusing on the needs of its customers.

Flexible production of different drive types at the Wörth plant

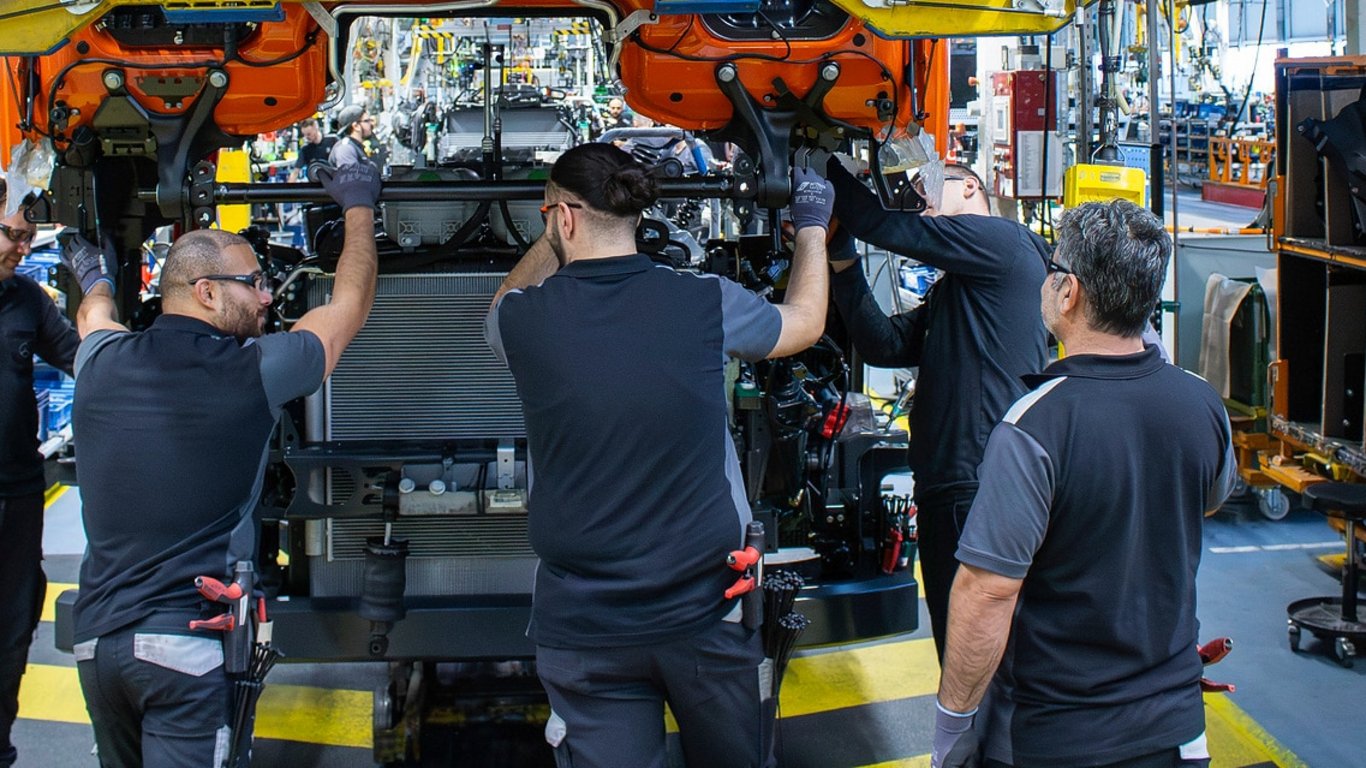

The new models will be manufactured on the existing assembly line for the Wörth A-series. There, battery-electric trucks will be produced in parallel and flexibly alongside diesel-powered models. This enables the plant to respond quickly to market demand and reliably meet the demanding quality standards of Mercedes-Benz.

Unlike the first-generation eActros models, which were electrified at the separate Future Truck Center in Wörth, this step in the production process for the new model generation is carried out entirely within the production hall. This means that the assembly of the electric trucks is fully integrated into the regular series production process, from frame construction to final inspection.

The Daimler Truck plants in Mannheim, Kassel, and Gaggenau also make key contributions to production: they supply essential components of the electric powertrain, including the electric axle, transmission components, and the so-called front box. This box bundles numerous high-voltage and low-voltage elements and is located in the former installation space of the combustion engine.

About the eActros 400 and eActros 600

The new eActros 400 with two LFP battery packs of 207 kWh(1) each has a total installed capacity of 414 kWh – hence its model number. Depending on the configuration and application profile, different ranges(2) are possible: in heavy-duty distribution transport, a partially loaded eActros 400 6x2 with a dry box body can achieve up to approximately 480 kilometers without recharging(3) at an ambient temperature of 20°C. The eActros 400 with two battery packs has a lower vehicle weight and therefore offers more payload than the eActros 600 with three battery packs – over three tons more – putting it on a par with comparable diesel trucks (more than 25 tons payload). The standard charging capacity is up to 400 kW via CCS2; two battery packs can be charged from ten to eighty percent in around 46 minutes(4).

The eActros 600 has three battery packs with a total installed battery capacity of 621 kWh(1) – hence the designation 600. This enables a range of 500 kilometers (2) without intermediate charging – and significantly more depending on equipment, driving style, route, and other influencing factors. The eActros 600 has been delivered to customers since December 2024 and is now in daily use on the roads in over 15 European countries. Even before it went into series production, it proved its capabilities under real-world conditions as part of the “eActros 600 European Testing Tour 2024,” a fully electric development drive covering over 15,000 kilometers through a total of 22 countries, as well as the “European Testing Tour Winter 2025” covering around 6,500 kilometers through Northern Europe – each with a total train weight of 40 tons.

About the Mercedes-Benz Wörth plant

About the Mercedes-Benz Trucks segment

Sustainability is an integral part of the strategy at Mercedes‑Benz Trucks. As part of Daimler Truck AG, Mercedes‑Benz Trucks pursues a clear goal: to decarbonize road freight transport step by step and drive the transformation of the transport industry forward. With battery‑electric and hydrogen‑based drive solutions, digital services, and climate‑friendly, resource‑efficient production and supply processes, Mercedes‑Benz Trucks is shaping the path toward locally CO₂e‑free transport across the entire value chain. With its safety and assistance systems as well as automated driving functions, Mercedes‑Benz Trucks also makes an important contribution to road safety. In doing so, Mercedes‑Benz Trucks plays a key role in Daimler Truck AG’s sustainability strategy.